Written by Rebecca Turley

It’s now infamously referred to as the Great Supply Chain Disruption—the global supply chain meltdown resulting from the events of COVID-19. And in its wake, a new era of supply chain management is emerging, one in which companies of every size and reach are re-examining supply chain resiliency and looking for new ways to gain a competitive edge while minimizing risk.

The buzz words say it all – risk management, resilience, smart logistics solutions, advanced analytics, artificial intelligence (AI)… today’s supply chains are smart, highly resilient, and designed to withstand volatility in the markets while addressing issues of sustainability in a global economy.

Some of the biggest and most significant changes to come along in a generation are emerging right now. It’s the professionals who develop the skills to navigate the brave new world of supply chain management who will be prepared to weather the next storm – or steer around it altogether.

Big Data and Analytics

Supply chain analytics uses data and quantitative methods to improve how we approach every aspect of supply chain and logistics management. It’s been a gamechanger, expanding the data being fed into SCM systems and allowing analysts to extract useful information using powerful tools and statistical methods.

Data-driven processes like inventory management and operations planning become supercharged, providing supply chain managers with both real-time and predictive data and new insights that allow them to make informed, strategic decisions at any point along the supply chain.

For example, big data allows companies to analyze inventory data, POS data, and more in real-time to quickly identify disparities between supply and demand. They can then quickly drive the actions to remedy any discrepancies without missing a beat. The collected data is also analyzed to make predictions about future supply and demand.

Amazon is a great example of a company that leverages big data to inform their decisions. They’ve implemented “anticipatory shipping,” which involves analyzing data to make decisions regarding what they expect their customers to buy and when. Teams predict where products should be stocked, directing them to the appropriate fulfillment centers so the products are close to the people who want to buy them.

From manufacturers to suppliers, everyone can benefit from the use of big data. For example, trucking companies frequently use fuel consumption analytics and real-time routing of deliveries to drive efficiency. Retailers use analytics to do everything from optimizing shelf space to deciding which products should be placed in high-value locations. And there’s even some who use satellite imagery to keep track of car traffic in parking lots to anticipate in-store demand even before sales numbers are in.

Artificial Intelligence and Machine Learning

At this moment, there is no other area of supply chain management that gets as much attention as artificial intelligence and machine learning – and for good reason. No longer science fiction, it’s delivering new insights across the supply chain just as it is in dozens of other industries.

The big data analytics that’s changing the face of the supply chain? Well, AI is sorting, analyzing, and making sense of it all and creating processes and systems that utilize it to adapt and learn. Thanks to AI and machine learning coupled with light tracking hardware (IoT!), inventory keeps track of itself, with shipments generating real-time reports used to inform future processes in a continual cycle of learning, adapting, and streamlining.

AI and machine learning helps improve demand forecasting, delivers data transparency, helps automate tracking and analytics tasks previously performed manually, improves visibility at all points along the supply chain, reduces shipping times to ensure on-time deliveries, while improving transportation networks and routes.

And we’ve only just begun to tap into the power of AI.

Smart Logistics and the Internet of Things (IOT)

The Internet of Things (IoT) in combination with analytics brings a whole new level of optimization to the supply chain process.

IoT collects the data from Internet-connected devices, and then processes, stores, and analyzes it in the cloud where companies can monitor it and make changes as needed. IoT manages real-time data on everything from inventory levels to storage levels to shipment status to environmental conditions in warehouses.

IoT combines the power of analytics with cloud and mobile computing to allow companies to better manage their supply chain networks. IoT’s value is clear – it allows companies to track logistics and operations and prevent one problem from affecting other parts of the supply chain. As a result, it helps eliminate bottlenecks in the supply chain and elevates contingency planning and risk mitigation efforts.

Intelligent Robotics

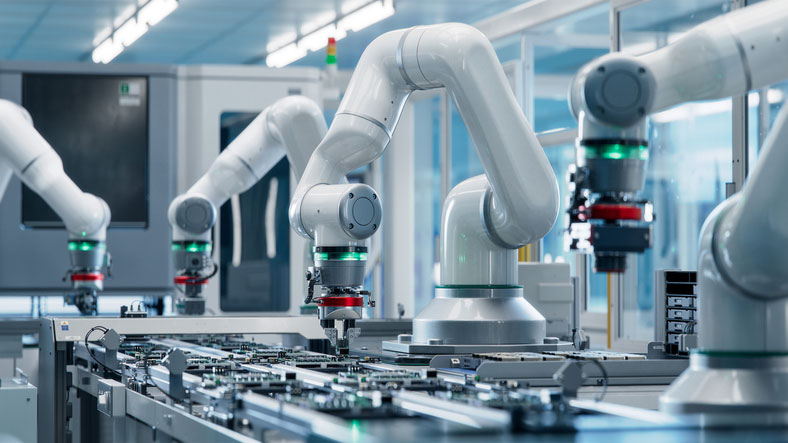

Labor shortages have become a lasting consequence of the COVID pandemic, spurring companies along the supply chain to begin exploring the benefits of intelligent robotics.

Thanks to advancements and the proliferation of robots in warehousing and other areas of logistics, robotics have become more affordable. Companies of all sizes now take advantage of the cost-effectiveness and efficiency they bring to manufacturing facilities, warehouses, and transportation processes.

Intelligent robotics, a growing category that includes stationary robots, mobile robots, and aerial (drone) robots, can all be programmed to perform specific tasks with little to no variation in speed and precision. The newest generation of intelligent robots are deployed with AI capable of recognizing and evaluating their surroundings to make independent decisions.

Intelligent robotics are often found working alongside humans to increase efficiency and improve the speed and accuracy of operations in warehousing and manufacturing settings. And in some cases, they fully replace human workers. For example, companies use robots to complete dangerous tasks or work in dangerous environments to protect employee health and safety.

Data Security and Cybersecurity

The more we rely on technology in the supply chain, the more vulnerable to cyberattacks the supply chain becomes. As a result, cybersecurity continues to lead the pack when it comes to the biggest trends in supply chain management. Data security is no longer an afterthought or an IT-only problem for companies, as breaches to any part of the supply chain can compromise sensitive information and security and cause operations to come to a grinding halt. Companies today are making significant investments in hardening and redundancies, employing advanced anti-hacking technologies to keep their supply chain systems safeguarded. And in cases where attackers do gain access, protocols help contain and mitigate damage allowing for quick recoveries.

In supply chain management, cybersecurity is a major issue because companies aren’t just protecting their own security, they’re dealing with lapses in security from supply chain partners too. Supply chain breaches can come from third-party vendors or service providers, enterprise software and even hardware, third-party data storage or data aggregators, and more.

Sustainable Supply Chains

Today’s supply chains touch every corner of the world. That means the way companies choose to conduct business has the potential to affect everything from the health of our planet to the fair treatment of workers. Companies today are focused on creating supply chain systems that prioritize responsible, restorative, and regenerative practices that aren’t just good for people and the planet, but also good for the bottom line. In recent years, companies both large and small have made pledges to work with supply chain partners who are committed to maintaining ethical and responsible social and environmental standards.

Sustainable supply chain management is an important part of a company’s overall environmental, social and governance (ESG) efforts. Companies now regularly look for ways to embed sustainability into their supply chain operations. The responsible use of natural resources, eliminating waste, decarbonation, ethical sourcing, fair trade, and ethical labor practices are some of the ways companies are looking to create sustainable supply chains.